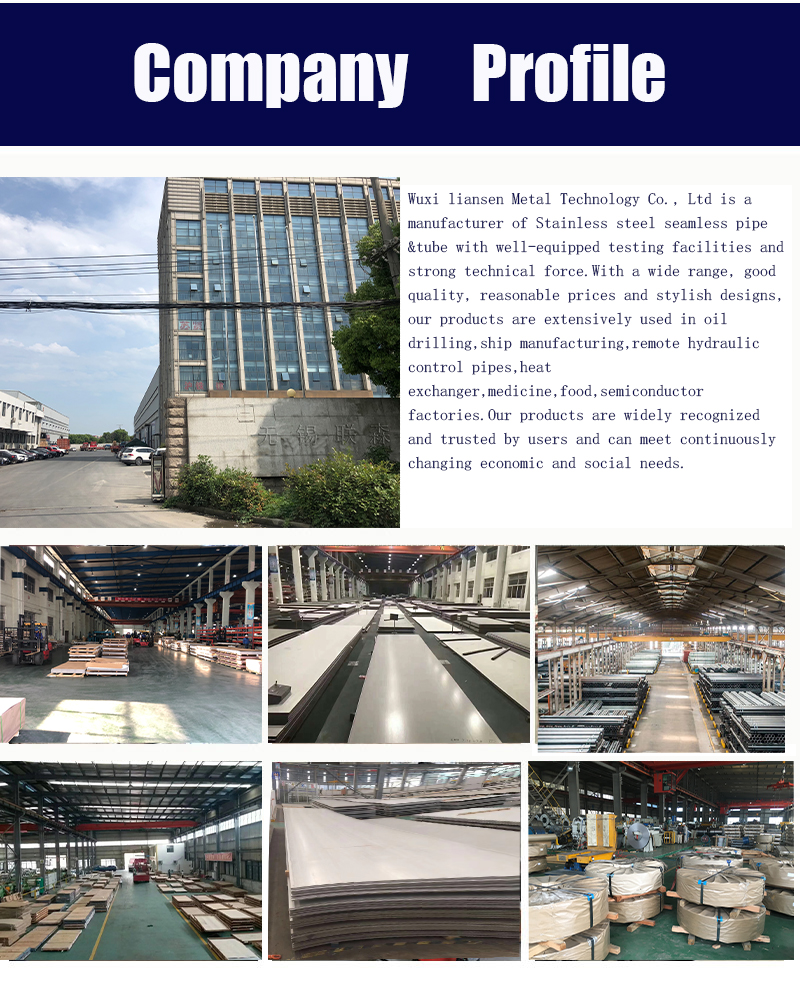

Source:Wuxi liansen Metal Technology Co., Ltd Release time:2021-11-10 13:24:38 Author:3202

Stainless steel first appeared about a hundred years ago, but it has recently begun to be widely used in construction and architecture. It was used in the construction and design of the largest shopping centers, for example, La Defense in Paris, Canary Wharf in London, Sony Center in Berlin, and Petronas Towers in Kuala Lumpur.

Today it is one of the most popular metal alloys both in production and in everyday life. Metal has been easily integrated into everyday life, becoming the basis for the creation of many household appliances, decorative items, and even utensils. This is due to its excellent use properties in comparison with analogs from other alloys.

This type of steel is robust to rust due to the chromium concentration of 12% and more. A combination of chromium and steel forms chromium oxide, which creates a surface-protective film from adverse effects. The modern market can offer an ERW tube and various types of this metal for use in numerous industrial sectors. With an increase in chromium concentration, the corrosion resistance of steel increases. This is inherent in the alloy not only in atmospheric conditions but also in a few other aggressive environments. It can also be said that this sort of metal better resists corrosion damage with an increase in the concentration of oxidizing agents in the environment since the electrode potential of the metal becomes more positive. This is not applicable for nitric acid, as, with an increase in its concentration, chromium steels are more vulnerable to corrosion attacks, and passivation occurs. At low concentrations, steel has a higher resistance force.

Chromium is a crucial component of the stainless-steel compound, and its combination

To provide it with additional characteristics and significantly improve existing properties, nickel, titanium, molybdenum, niobium, cobalt, etc. are introduced into its chemical composition. Such alloying allows you to create different types of stainless-steel that differ from each other in their characteristics and, accordingly, the purpose. Thus, nickel is used to achieve flexibility.

The characteristics possessed by this type of metal are determined both by the chemical composition of the alloy and the features of its internal structure. Depending on these parameters, it can be divided into four groups.

Ferritic

The chemical structure of this group contains about 12-30% of chromium (therefore, they are also called chromium). Due to the significant chromium content, products from such steel can successfully withstand the effects of even very aggressive environments. Steel alloys of this group are distinguished by good magnetic characteristics.

Large consumers of ferritic steel are enterprises of the heavy industries; for example, they produce elements of heating equipment, using the stainless alloys of this type. Alloys of the ferritic group occupy a rather large market share of this type of metal and, in terms of their demand, are only slightly inferior to materials with an austenitic internal structure, but they are much cheaper than the latter.

Austenitic

A significant proportion of the chemical composition of this type of metal (up to 33%) relates to nickel and, of course, chromium. Consumers prefer these alloys since such materials are characterized by durability and exceptional resistance to rust. It is the most popular type; for example, it is used for creating washing machine tubs and different equipment.

Martensitic

Thanks to the peculiarities of the internal structure, such alloys are characterized by the highest strength among steels. In addition, they are characterized by good wear resistance and a minimum amount of harmful impurities in their composition. This category includes heat-resistant corrosion-resistant steel, capable of not only successfully resisting oxidative processes but also being operated under conditions of constant exposure to high temperatures, without losing its original characteristics.

Duplex

This type of metal has both ferritic and austenitic crystal lattice structures. Usually, this steel contains about 22-25% chromium and 5% nickel, which partially determines its austenitic structure. The duplex structure provides both durability and flexibility. Duplex steels are most often used in the petrochemical, pulp and paper industries, and shipbuilding.

Have a question? For immediate answers 24/7, try our Resource Center. It contains Frequently Asked Questions (FAQ), Resource Articles, and our Blog. We have real human beings that can help, too. If any inquiry for Stainless Steel and Carbon Steel . Please feel free to contact with us at alexzhang@liansen.vip and we will send you complete details within 16 hours.Or any any urgent information needed for stainless steel,please call us or send message by WhatsApp:0086-18012365661