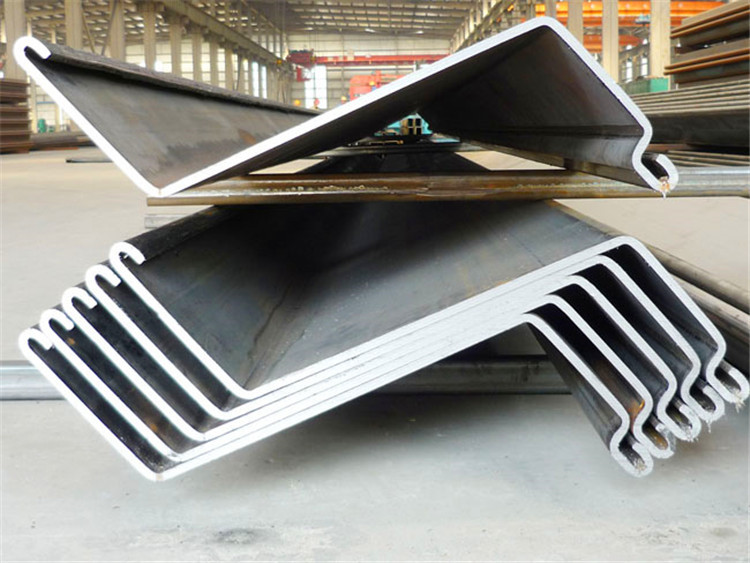

Z-shaped steel sheet piles, building materials, and Z-shaped steel sheet pile locks are symmetrically distributed on both sides of the neutral axis. Coupled with the continuity of the web, the section modulus of the steel sheet pile has been improved to a large extent. Ensure that the mechanical properties of the section are fully utilized.

Feature

1. The cross-section width is large, and the pile sinking effect is obvious.

2. The section modulus is large.

3. The higher moment of inertia enhances the rigidity of the steel sheet pile wall and reduces structural deformation.

4. Excellent anti-corrosion effect.

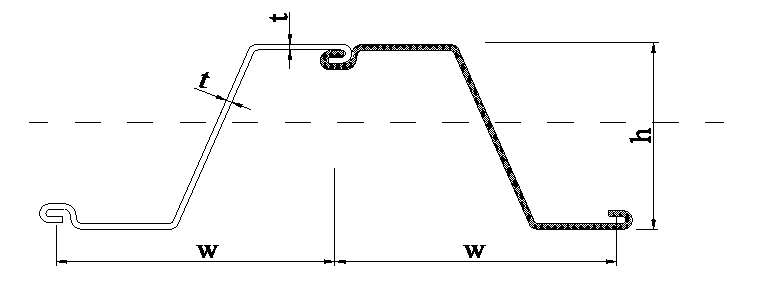

|

model |

Width |

Height |

Thickness |

Weight |

Wall per meter |

Moment of inertia |

Section modulus |

|

|

|

mm |

mm |

mm |

Kg/m |

Kg/ m2 |

Cm4/m |

Cm3/m |

|

|

LS16-635 |

635 |

379 |

7 |

61.5 |

96.9 |

30502 |

1610 |

|

|

LS18-635 |

635 |

380 |

8 |

70.1 |

110.3 |

34717 |

1827 |

|

|

LS28-635 |

635 |

419 |

11 |

104.2 |

164.1 |

28785 |

2805 |

|

|

LS30-635 |

635 |

420 |

12 |

113.3 |

178.4 |

63889 |

3042 |

|

|

LS32-635 |

635 |

421 |

13 |

122.3 |

192.7 |

68954 |

3276 |

|

|

LS12-650 |

650 |

319 |

7 |

57.8 |

88.9 |

19603 |

1229 |

|

|

LS14-650 |

650 |

320 |

8 |

65.8 |

101.2 |

22312 |

1395 |

|

|

LS14-700 |

700 |

419 |

7 |

61.5 |

87.8 |

30824 |

1471 |

|

|

LS16-700 |

700 |

420 |

8 |

70.0 |

100.0 |

35074 |

1670 |

|

|

LS22-700 |

700 |

419 |

9 |

87.1 |

124.5 |

47058 |

2246 |

|

|

LS25-700 |

700 |

420 |

10 |

96.5 |

137.9 |

52095 |

2491 |

|

|

LS30-700 |

700 |

449 |

11 |

111.8 |

159.7 |

67025 |

2986 |

|

|

LS32-700 |

700 |

450 |

12 |

121.6 |

173.7 |

72863 |

3238 |

|

|

LS36-700 |

700 |

500 |

12 |

125.2 |

178.9 |

91788 |

3672 |

|

|

LS40-700 |

700 |

501 |

13 |

135.2 |

193.2 |

99086 |

3956 |

|

|

LS44-700 |

700 |

551 |

13 |

139.1 |

198.8 |

121982 |

4428 |

|

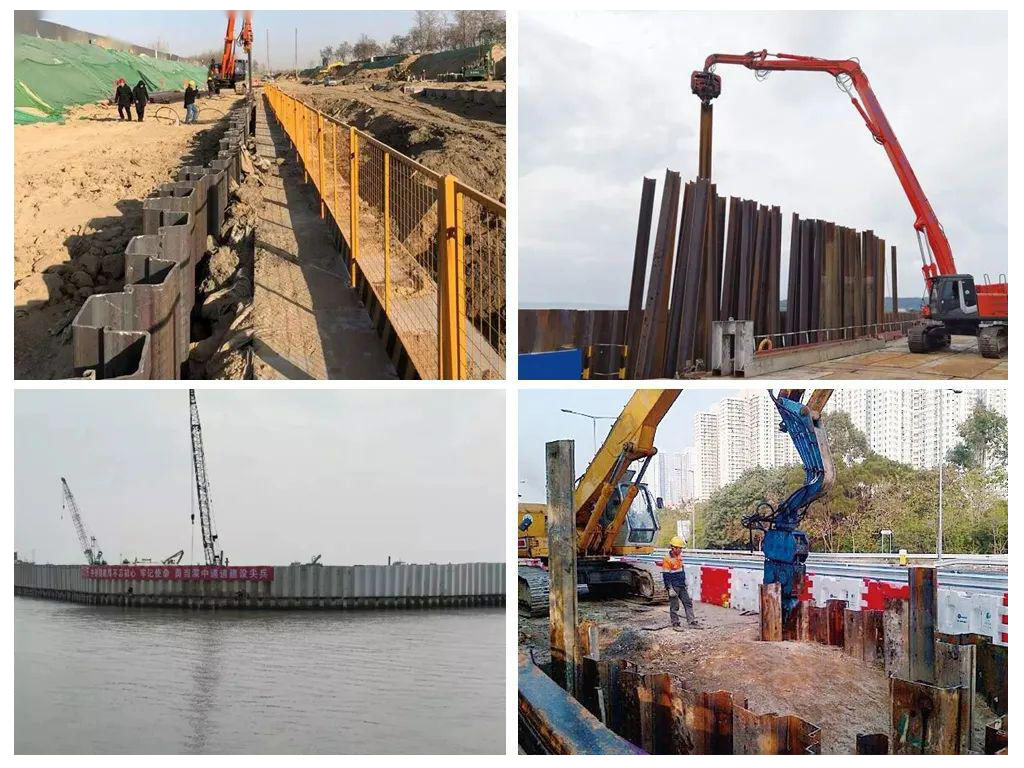

Z-type steel sheet piles are widely used in automobiles, railway vehicles, shelves, electrical cabinets, highway guardrails, building steel structures, containers, transmission towers, steel sheet piles, cable bridges, agricultural machinery, furniture, vegetable greenhouses, pipe supports and other fields.