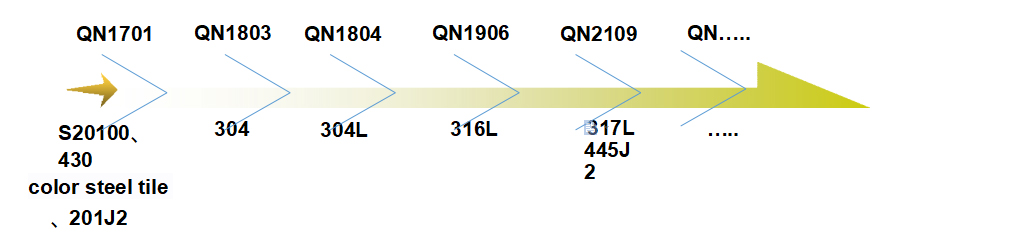

QN series products are the first new austenitic stainless steel in the world. At present, there are five varieties —— QN1701, QN1803, QN1804, QN1906 and QN2109, about 15-30 PREN(Pitting Resistance Equivalent), equivalent to American standard 201/430, 304, 304L, from 316L to 317L. The product has the characteristics of high corrosion resistance, high strength, high wear resistance, easy processing, easy welding, etc. At the same time, the high nitrogen nickel design reduces the alloy cost and improves the technical added value of products, so it has the advantage of high cost performance. QN series products have become the national standard and the group standard of CISA(China Iron and Steel Association). They are widely used in the fields of construction, decoration, kitchen and bathroom, products and Marine ranching, leading the innovation of stainless steel varieties and standards.

|

Publishing Unit |

Standard no. |

Grant standard Name |

Application area |

|

China Iron and Steel Association China Metallurgical information and standardization institute |

T/CISA 045-2020 |

Cr - Mn - NI - N austenitic stainless steel hot-rolled sheet and strip |

Plate and strip |

|

T/CISA 046-2020 |

Cr - Mn - NI - N austenitic stainless steel hot-rolled sheet and strip |

Plate and strip |

| Type |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

Cu |

N |

Nb+Ti |

PREN |

|

201J2 |

0.152 |

0.44 |

9.12 |

0.047 |

0.0025 |

13.15 |

1.25 |

0.03 |

0.36 |

0.167 |

/ |

9.14 |

|

430 |

0.042 |

0.32 |

0.25 |

0.028 |

0.001 |

16.15 |

0.12 |

0.01 |

0.04 |

0.040 |

/ |

16.18 |

|

QN1701 |

≤0.15 |

≤1.00 |

5.00- |

≤0.06 |

≤0.010 |

16.00- |

1.00- |

≤0.6 |

0.80-3.00 |

0.20-0.30 |

/ |

>15.0 |

|

304 |

0.040 |

0.40 |

1.05 |

0.035 |

0.0021 |

18.11 |

8.02 |

0.02 |

0.12 |

0.045 |

/ |

18.51 |

|

QN1803 |

≤0.10 |

≤1.00 |

4.00- |

≤0.05 |

≤0.005 |

17.50- |

2.00- |

≤0.6 |

1.00-3.50 |

0.20-0.30 |

/ |

>19.0 |

|

304L |

0.020 |

0.42 |

1.02 |

0.034 |

0.0019 |

18.17 |

8.03 |

0.04 |

0.13 |

0.046 |

|

18.66 |

|

QN1804 |

≤0.06 |

≤1.00 |

4.00- |

≤0.05 |

≤0.005 |

17.50- |

3.00- |

≤0.6 |

1.00-3.50 |

0.20-0.30 |

|

>18.5 |

|

316L |

0.021 |

0.4 |

1.25 |

0.032 |

0.001 |

16.6 |

10.05 |

2.04 |

0.1 |

0.035 |

/ |

23.13 |

|

QN1906 |

≤0.06 |

≤1.00 |

2.00- |

≤0.045 |

≤0.005 |

18.00- |

5.00- |

0.50- |

1.00-3.50 |

0.20-0.30 |

/ |

>24.0 |

|

445J2 |

0.010 |

0.25 |

0.10 |

0.023 |

0.001 |

22.30 |

0.10 |

1.80 |

0.06 |

0.011 |

0.42 |

28.24 |

|

317L |

0.016 |

0.38 |

1.45 |

0.026 |

0.001 |

18.12 |

12.66 |

3.05 |

0.08 |

0.044 |

|

28.89 |

|

QN2109 |

≤0.06 |

≤1.00 |

1.00- |

≤0.045 |

≤0.005 |

20.00- |

8.50- |

1.00- |

1.00-3.50 |

0.20-0.30 |

|

>29.0 |

|

Type |

Density 3 (g/cm ) |

Specific Heat Capacity KJ/(kg*K) |

Thermal Conductivity W/(m*K) |

Thermal Diffusivity (mm2/s) |

Coefficient of Thermal Expansion 10 /K |

Electrical Resistivity Ω*mm2/m |

Elasticity Modulus kN/mm2 |

|

201J2 |

7.81 |

0.65 |

20.6 |

4.06 |

16.5 |

0.67 |

195 |

|

430 |

7.75 |

0.46 |

26.0 |

/ |

10.5 |

0.60 |

200 |

|

QN1701 |

7.84 |

0.76 |

23.6 |

3.93 |

16.1 |

0.62 |

196 |

|

304 |

7.93 |

0.50 |

16.3 |

4.11 |

17.2 |

0.73 |

193 |

|

QN1803 |

7.83 |

0.67 |

20.7 |

3.96 |

16.8 |

0.72 |

196 |

|

304L |

7.90 |

0.50 |

16.3 |

/ |

16.8 |

0.73 |

193 |

|

QN1804 |

7.84 |

0.50 |

15.3 |

3.87 |

16.3 |

0.70 |

196 |

|

316L |

7.98 |

0.50 |

16.3 |

/ |

16.0 |

0.74 |

193 |

|

QN1906 |

7.90 |

0.59 |

17.2 |

3.67 |

17.3 |

0.74 |

196 |

|

445J2 |

7.75 |

/ |

22.5 |

/ |

10.5 |

/ |

/ |

|

317L |

7.98 |

0.50 |

14.4 |

/ |

16.5 |

0.79 |

200 |

|

QN2109 |

7.90 |

0.59 |

15.1 |

3.21 |

16.1 |

0.79 |

197 |

| Type |

Thickness mm |

Tensile Strength Rm(MPa) |

Yield Strength Rp0.2(MPa) |

Elongation A50% |

Hardness HV |

180° Cold Bend |

|

201J2 |

0.5 |

915 |

410 |

51.5 |

240 |

Intact |

|

430 |

0.5 |

540 |

285 |

31.5 |

145 |

Intact |

|

QN1701 |

0.5 |

760 |

450 |

55.5 |

240 |

Intact |

|

304 |

0.5 |

670 |

290 |

58.5 |

165 |

Intact |

|

QN1803 |

0.5 |

747 |

432 |

51.6 |

230 |

Intact |

|

304L |

0.5 |

650 |

270 |

59.0 |

160 |

Intact |

|

QN1804 |

0.5 |

735 |

425 |

52.5 |

215 |

Intact |

|

316L |

0.5 |

630 |

265 |

59.0 |

152 |

Intact |

|

QN1906 |

0.5 |

742 |

420 |

49.5 |

210 |

Intact |

|

445J2 |

0.5 |

550 |

360 |

30.5 |

175 |

Intact |

|

317L |

0.5 |

640 |

340 |

50.0 |

165 |

Intact |

|

QN2109 |

0.5 |

720 |

415 |

48.5 |

196 |

Intact |

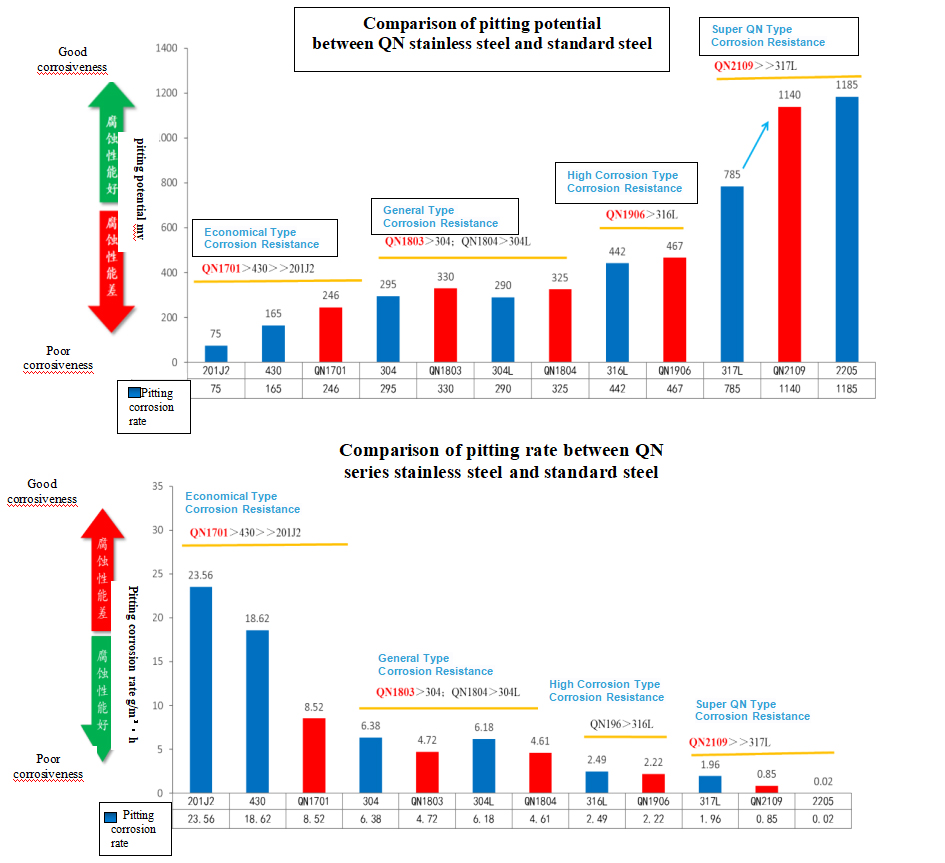

3.1Pitting Resistance

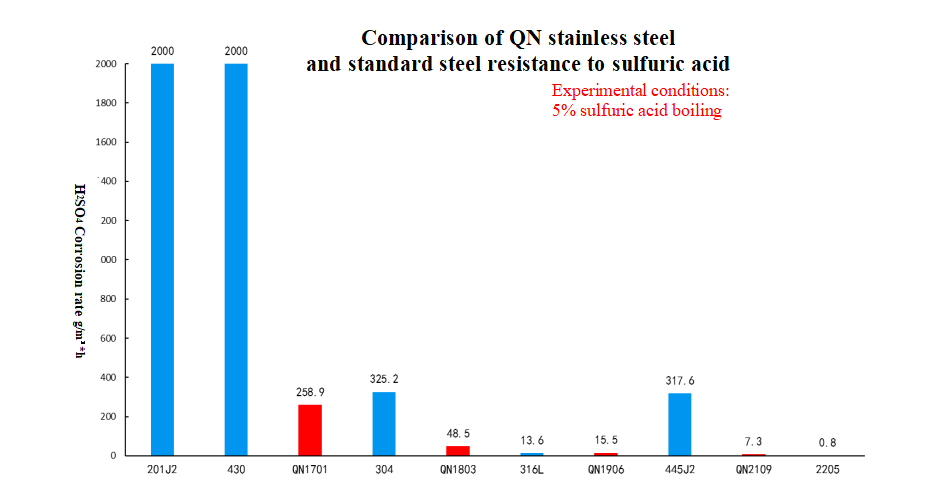

3.2 Sulfuric Acid Corrosion Resistance

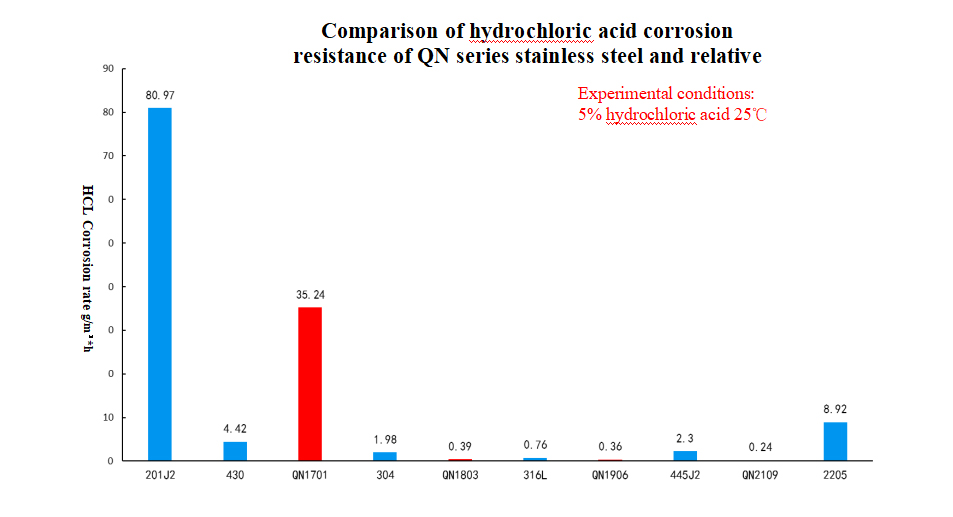

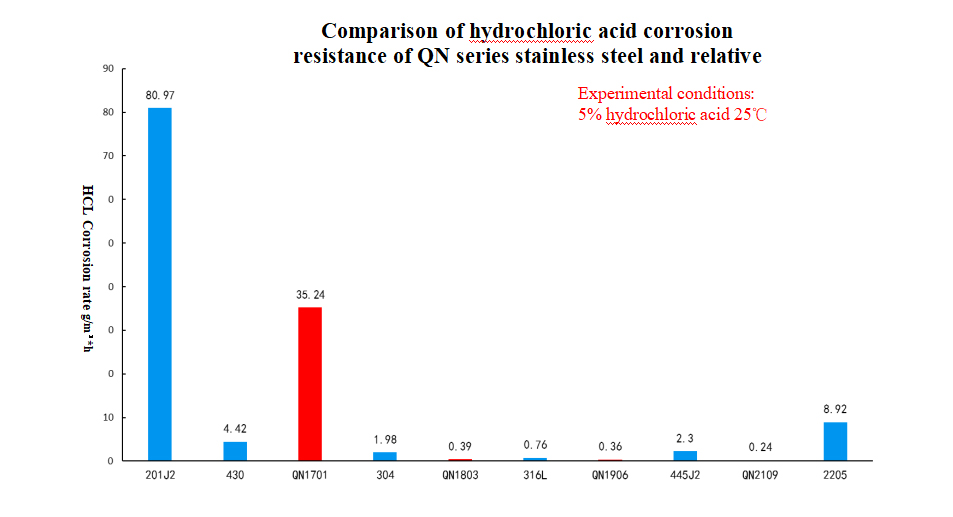

3.3 Corrosion Resistance of Hydrochloric Acid

4. High Cost Performance

To sum up, QN series products have the following characteristics:

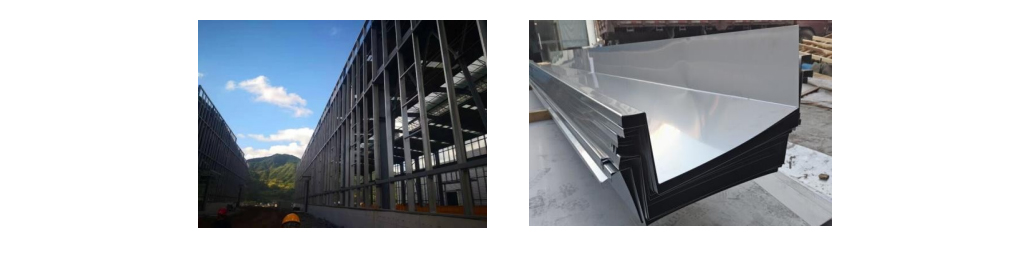

1. Building Roof and Curtain Wall

(1.)Excellent corrosion resistance, especially in sulfuric acid, hydrochloric acid and other workshop environment, QN system corrosion resistance is stronger.

(2.)The yield strength exceeds Q355 grade, far higher than Q235 grade of conventional austenitic stainless steel, which can reduce the material thickness and further achieve lightweight products.

(3.)Cost performance is higher than conventional stainless steel roofing and curtain wall.

Recommend corresponding QN stainless steel grade.

2.Stainless Steel Purlin, Gutter

Cost performance advantage

(3)The cost performance is higher than the conventional stainless steel used in purlin and gutter.

Recommend corresponding QN stainless steel grade.

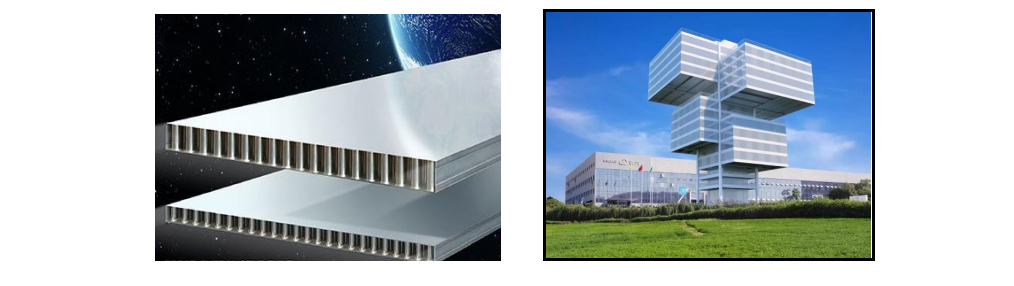

3.Prefabricated Buildings

Cost Performance Advantage

(2)It has higher strength than 304 at room temperature and high temperature.In case of fire and other emergencies, the safety is higher.

Recommended material: QN1804

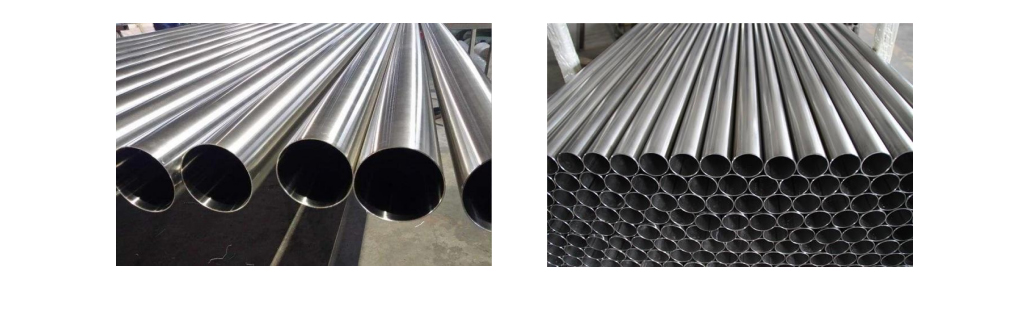

4 .Stainless Steel Decorative Welded Pipe

Cost Performance Advantage

(2)Cost performance is higher than conventional stainless steel decorative welding pipe.

(3)Recommended materials: QN1701,QN1803

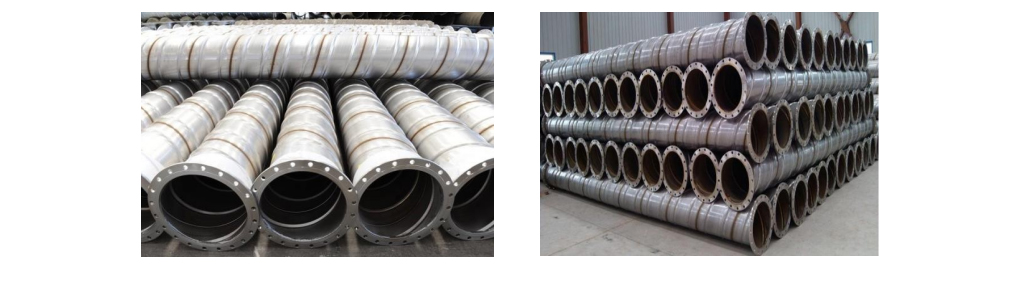

5.Drain Pipe and Fire Hose

Cost Performance Advantage

(3)More cost-effective than conventional stainless steel drainpipes and fire hoses.

6.Slide Rail Hinge

Cost performance advantage

Recommended material: QN1803

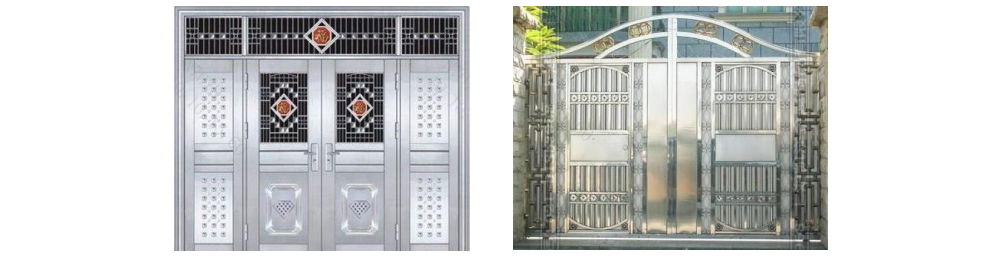

7.Hardware Door Industry

Cost Performance Advantage

(2)The cost performance is higher than that of conventional stainless steel used in hardware door industry.

8.The Panels of the Elevator

Cost Performance Advantage

(2)It is used for elevator panel, which is more wear-resistant and scratch resistant.

(3)The cost performance is higher than that of conventional stainless steel for elevator panel.

Recommended material: QN1803

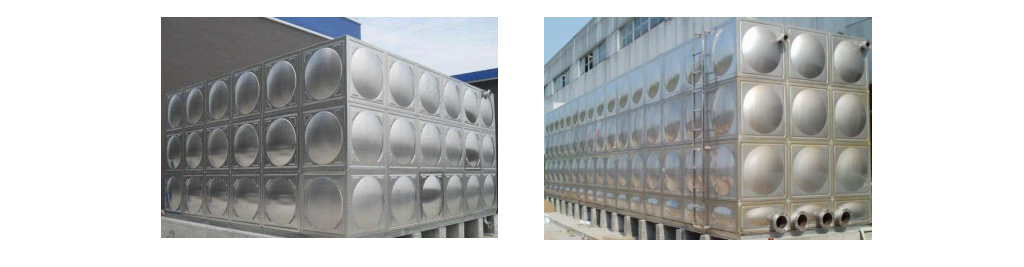

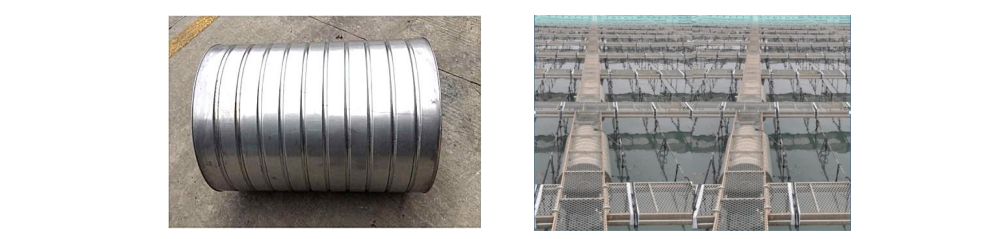

9.Tank

Cost Performance Advantage

(1)QN series is used in the water storage tank industry to ensure excellent corrosion resistance and longer service life.

(2)It has copper containing design, has significant antibacterial effect, has less risk of breeding bacteria in water storage, and is safer and healthier.

(3)The cost performance is higher than that of conventional stainless steel for water storage tank.

10.Kitchen and Bathroom Products

Cost Performance Advantage

(1)QN1803 has better corrosion resistance than 304 under the complex conditions of weak acid and salt commonly used in kitchens such as acetic acid + sodium chloride.

(2)QN1803 is better than 304 in pitting and crevice corrosion resistance. It is very suitable for making floor drains and other products with crevices.

(3)It meets the Japanese Standard JIS antibacterial standard, and the 4-hour sterilization rate reaches more than 99.9%.

(4)The migration test of heavy metals complies with national standards, EU standards and German LFGB.

Recommended materials: QN1803 & QN1804

11.Cookware Products

Cost Performance Advantage

(1)Its corrosion resistance under the common weak acid + salt compound condition in the kitchen is better than 304.

(2)It meets the Japanese Standard JIS antibacterial standard, and the 4-hour sterilization rate reaches more than 99.9%.

(3)Its heavy metal migration test complies with national standards, EU standards and German LFGB. It is a food grade cooking material.

Recommended materials: QN1803 & QN1804

12.Cold Container

Cost Performance Advantage

(1) QN1803 has higher pitting potential than 304, better Cl ion corrosion resistance and excellent corrosion resistance.

(2) Goodweld-ability and low temperature (-40 ℃) tensile properties.

Recommended material: QN1803

13.Live Stock Equipment

Cost Performance Advantage

(1) The livestock equipment made of QN1803 material ensures better corrosion resistance than 304.

(2) QN material has high strength, more resistant to livestock extrusion and arching, maintenance free, more environmental protection and longer service life.

Recommended materials: QN1803 (Trough) & QN1701(Fence)

14.Gas Pipeline

Recommended material: QN1803

15.Oceanic Ranch

Cost Performance Advantage

(1) QN series is used in the field of oceanic ranch to ensure excellent corrosion resistance and longer service life.

(2) The yield strength of QN material reaches 355MPa, which is more than 1.30 times that of 316L stainless steel. This ability to resist seawater erosion and wave attack is stronger.

(3) the cost performance is much higher than that of traditional marine pasture materials (wood and foam).

Recommended material: QN2109

16.Desulfurization column

17.Chemical tank

» Compared with the conventional steel with the same corrosion resistance, QN series can reduce the production cost by more than 20%.

» Compared with conventional steels with the same corrosion resistance, QN series gradually replaces some traditional high nickel and high cost austenitic stainless steels by virtue of its perfect combination of strength, corrosion resistance and cost performance.

» It will become the mainstream product series of stainless steel in the future and lead the innovation direction of stainless steel varieties.