COLD ROLLED is the further thinning of steel plates at room temperature below the recrystallization temperature to the target thickness of steel plates.Compared with hot rolled steel sheet, cold rolled steel sheet thickness is more accurate, and the surface is smooth and beautiful.

|

Product |

Cold Rolled Stainless Steel Plate |

|

Thickness |

0.2-4.0mm,etc |

|

Width |

500-2000mm,etc |

|

Length: |

2000mm, 2438mm, 3000mm, 3500,6000mm,9000,or rolled,etc etc |

|

Standard: |

ASTM,AISI,JIS,GB, DIN,EN |

|

Surface |

Black painted,PE coated,Galvanized,color coated, |

|

anti rust varnished,anti rust oiled,checkered,etc |

|

|

Technique: |

Cold Rolled |

|

Certification: |

ISO, SGS,BV |

|

price terms |

FOB,CRF,CIF,EXW all acceptable |

|

Delivery Detail |

inventory About 5-7; custom-made 25-30 |

|

Loading port |

any port in China |

|

Packing |

standard export packing (inside:water proof paper,outside:steel covered with strips and pallets) |

|

Payment Terms |

T/T, L/C at sight,West Union,D/P,D/A,Paypal |

|

Container size |

20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) |

|

40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) |

|

|

40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) |

Cold rolling: hot rolled steel coil is used as raw material, after pickling to remove the oxide skin for cold continuous rolling, the finished product is rolled hard coil, because of continuous cold deformation caused by cold work hardening, the strength and hardness of the rolled coil increase, the toughness and plastic indicators decline, so the stamping performance will deteriorate, can only be used for simple deformation parts.Rolled coil can be used as the raw material of hot dip galvanizing plant, because hot dip galvanizing unit is equipped with fire line.The rolled roll weight is generally 6~13.5 tons, and the hot rolled pickling roll is rolled continuously at room temperature.The inner diameter is 610mm.

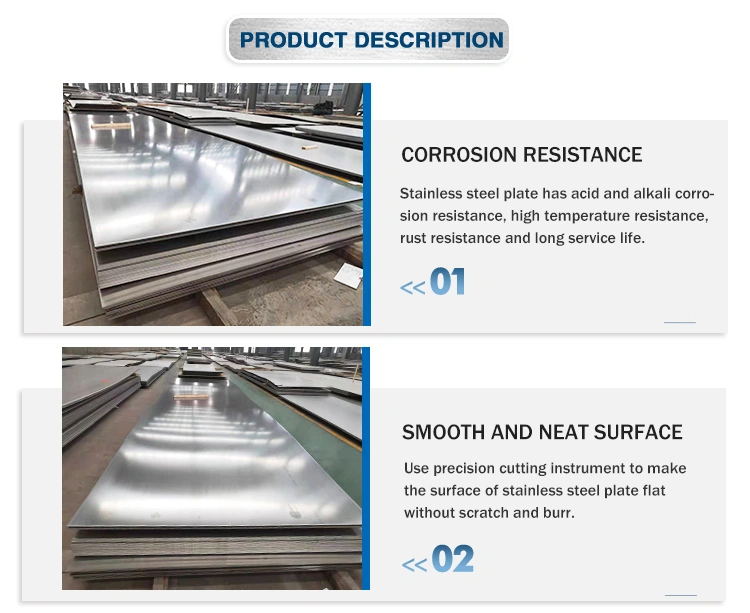

Cold Rolled Stainless Steel Plate features: because it has not been annealed, its hardness is very high (HRB is greater than 90), the mechanical processing performance is very poor, can only be simple directional less than 90 degree bending processing (perpendicular to the winding direction).

To put it more simply, cold rolling is the process of rolling on the basis of hot rolled coil, generally speaking, the process of hot rolling - pickling - cold rolling.

Cold rolling is made of hot rolled plates at room temperature, although it is called cold rolling in spite of the fact that rolling also heats up the plates during the process.Because the hot rolling after the continuous cold deformation of cold rolling, the mechanical performance is poor, hardness is too high.It must be annealed to recover its mechanical properties.Rolled coil is generally used to make products without bending and stretching.

Cold Rolled Stainless Steel Plate is widely used, such as automobile manufacturing, electrical products, rolling stock, aviation, precision instruments, canned food and so on.Cold-rolled thin steel plate is the common carbon structure steel cold-rolled short, also known as cold-rolled plate, commonly known as cold plate, sometimes mistakenly written as cold tie plate.Cold plate is made of ordinary carbon structural steel hot rolled steel strip, after further cold rolling into the thickness of less than 4mm steel plate.As a result of rolling at room temperature, do not produce iron oxide, so, cold plate surface quality, high dimensional accuracy, coupled with annealing treatment, its mechanical properties and technological performance are better than hot rolled thin steel plate, in many fields, especially home appliances manufacturing field, has gradually replaced the hot rolled thin steel plate.